The HRU Series achieve precise temperature and relative humidity control using its DDC in-built Fuzzy Logic Controller without incorporating any heater element. The DDC Controller changes the variable speed drive of DX compressor in the DX Heat Recovery System and the air flow rate across the DX Coil of AHU to precisely control to achieve the desired temperature and humidity set-point.

HRU Series

Energy DX Heat Recovery System

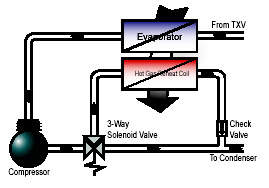

When compressor is running to reduce room temperature (sensible heat) and humidity (latent heat) respectively, it normally runs beyond the room temperature set point to continue the dehumidifying process. When the right humidity level has been achieved, the system requires reheating to compensate for the overcooling. Usually, electric heaters are used.

In our DX Heat Recovery System Solutions, we re-use the waste heat energy from the discharged superheat gas. The technology allows us to precisely control the hot gas flows through the reheat coil using a solenoid valve linked to our DDC fuzzy logic controller. This unique implementation allows us to save as much as 30% of energy as compared to heating element based system*.

Hot Gas Reheat Coil System

Precision Temperature and Humidity Control

Traditionally, constant room temperature and humidity is maintained by starting and stopping the compressor through a PID controller. During the “stopping phase”, room humidity fluctuates due to the room latent heat.

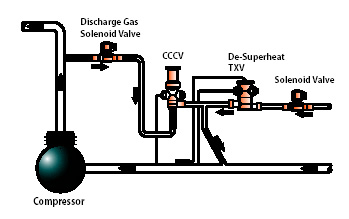

Enercov has developed a new improved proprietary technology, the Compressor Capacity Control Valve (CCCVTM ) system, to “unload” the compressor during low load condition down to 50% of the original compressor capacity. The CCCVTM bypasses an appropriate amount of discharged refrigerant gas back to the suction line based on the actual room heat load. The mechanism self-regulates the refrigerant quantity flows to the evaporator based on room heat load specification, giving precision temperature and humidity control. Our CCCVTM technology can achieve a room temperature error of less than +/ -0.5℃ and humidity error of less than +/- 3 %RH of the desired controlled range.*

Hot Gas By Pass System with Compressor Capacity Control Valve (CCCV™)

Wide Sensible and Latent Heat Operation Range

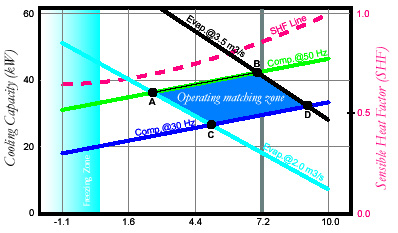

Using Variable Speed Drive (VSD), Enercov’s System Solution implements an Advantage Speed Control for both the compressor and supply air fan (SAF) enabling a large Sensible and Latent Heat control range. The wide operating range for the compressor also drives up the efficiency of the compressor, giving further energy savings. With a variable compressor loading capability and wide sensible and latent heat operation point, the additional energy savings can be as much as 20%*.

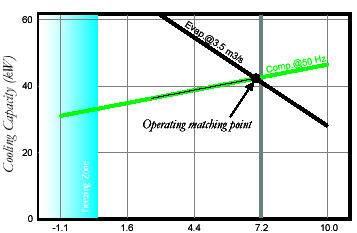

a. Matching Capacity of conventional air conditioner

b. Matching Capacity of ENERCOV System Solution

Compressor & Supply Fan variable speed matching curve

ENERCOV HRU operating limitation

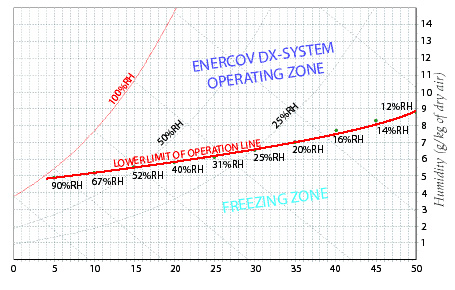

Enercov HRU Solution can operate in most demanding conditions, such as the semiconductor, precision manufacturing, bio-technology, hospital environments.

The theoretical limit of the technology allows the energy saving solution to be deployable in most application without added heat element.

The HRU Solution can also be used to control room pressure for negative /positive applications.

Graph for Lower limit of operation line

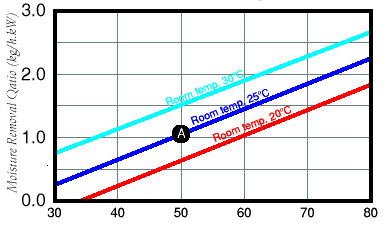

Max. Moisture Removal Performance Curve

Graph for Moisture Removal Ratio in case of Dehumidifying Mode

*under certain environmental conditions